Test for poppet valve resistance model

The old WTCC regulations deliver a very special case to limit engine power. The main parts of the regulations where that the engine had to be a 2 liter with 4 cylinders.

Instead of limiting the amount of air by a restrictor, the regulations limited the maximum lift of the valves to 11 [mm]. In addition the maximum revs where limited to 8500 [rpm]. And the last step to limit the power, was the compression ratio of 11:1.

These regulations provide a very interesting opportunity to check the accuracy of the engine model.

Bore x Stroke:

Compression ratio:

Mechanical Losses:

86 x 86 [mm] (4 Cylinder)

11 : 1

0.8 [Bar]

Intake Valves:

Exhaust Valves:

2 x 34 [mm]

2 x 30 [mm]

Inlet Camshaft :

Exhaust Camshaft :

258 [mm] (@ 1 [mm] lift)

248 [mm] (@ 1 [mm] lift)

Intake runner:

Primary exhaust:

320 x 44 [mm]

650 x 40 [mm]

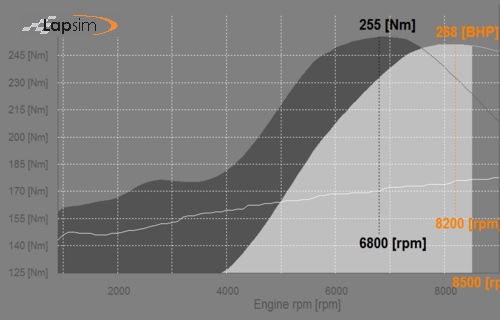

In reality they delivered between 270 - 275 [Hp]

Due to the regulations these engines delivered somewhere around 270 [HP].

The shown power graph is about the maximum which can be reached according to the simulation model.

Making optimal use of regulations

Because the maximum valve lift is limited to 11 [mm], one should use camshafts which keep the valves at the maximum lift for a while.

The engine simulation enables this option. Apart from these regulations, it might be that the construction of the engine also limits the maximum lift. That could be another reason to opt for this kind of cam profile.

Good test for 2-zone burn model

Due to the limit compression ratio of 11:1, the ignition can be run at the 'optimal' advance as can be seen in the figure.

The figure shows the influence of ignition advance on the delivered torque of the engine at 5000 [rpm].